Navigating the interior of a wind turbine can be challenging. Tight spaces, towering heights, and the constant threat of adverse weather make conditions difficult for those performing a wind turbine inspection.

ROVVER X RX95: Your Essential Tool for Safe and Efficient Wind Turbine Inspection

As a leader in innovative pipeline and sewer inspection equipment solutions, Envirosight is committed to providing cutting-edge technology that enhances efficiency, sustainability, and safety. Our new EV vans offer a unique approach to infrastructure maintenance, combining the latest in electric vehicle technology with advanced CCTV capabilities.

Topics: CCTV Inspections EV Vans

A sewer inspection report is acomprehensivesummary of the observations made during a visual sewer assessment. These reports are tools that help decision makers like engineers, QA/QC departments, IT departments and MRO teams make more informed decisions about how to manage and maintain their wastewater infrastructure.

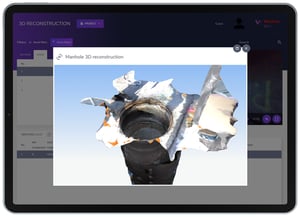

A digital twin is a virtual model that serves as a replica of a physical object, and which is designed to simulate its attributes and performance. To build this kind of model, you first need to gather data from the physical object in question. Sensors can produce information about the object’s performance that is then combined with geometric data gathered via technology like lidar, photogrammetry, laser scanning,time-of-flight camera or physical measurement. This data is processed to create an accurate, virtual representation--or digital twin--of the object. Once built, sensor data continues to update the digital twin in real time, helping it mirror to the original object’s state as much as possible.

Topics: WinCan Sewer Infrastructure

Over the last 50 years, the U.S. has experienced extreme droughts and a major population increase. It is now more important than ever to utilize new water sources and resource management tools to meet current and future water needs. One such source that is already being tapped is reused or recycled water. Reclaimed water and wastewater (hereafter referred to as simply “water”) are recovered from a variety of sources, then treated and reused in industrial processes, environmental restoration and agricultural irrigation, added to potable water supplies, and more.

How Augmented and Virtual Reality Enhance the Water and Wastewater Industries

In September 1998, American football fans witnessedsomething new on their televisions: a virtual, yellow line (representing the first-down line) superimposed on their screens. This was created by the engineers at Sportvision Inc., a company that providedvirtual viewing enhancements for sporting events. The first-down line is one of the earliest examples of augmented reality(AR)at work.

Topics: Sewer Infrastructure

Oftentimes, it’s hard to get a feel for a piece of inspection equipment until it’s right in front of you. As such, equipment demos are prime opportunities for determining exactly what you need from your new sewer inspection tool. To truly make the most out of an equipment demo, there are several things you should keep in mind.

Topics: Sewer Inspections Resources

Updating your asset management strategy is intimidating, especially when there are so many options to choose from. Moving from hardcopy reports to digital via the cloud is a particularly big step. This transition is made easier by advanced asset management software that’s made to fit your unique inspection needs. Across industries, WinCan sewer inspection software is simplifying the data and asset management process.

Topics: WinCan Industry Voices

Medical and public health experts agree: There is no “safe” level of lead in the human body. Unfortunately, many lead sewer and water pipes are still in place across the country; according to the United States Environmental Protection Agency (EPA), there are approximately 9.2 million lead service lines (pipes that connect homes to the water main) in the U.S. As these lines and other lead plumbing fixtures age, they’re at higher risk of corrosion and are therefore more likely to leach lead into water supplies. With this knowledge in mind, it’s essential that lead pipe replacement programs take center stage to protect public health.

Topics: EPA Health and Hygiene Regulations

On February 5, 2021, Oldsmar, Florida’s water treatment plant operators found themselves under attack. A hacker infiltrated the facility’s system and attempted to increase the water’s level of sodium hydroxide to over 100 times its normal amount. While sodium hydroxide is commonly used in water and wastewater treatment to remove heavy metal particles, large amounts of sodium hydroxide are poisonous to humans and can be deadly.