In the world of sewer assessment, visual pipe inspection tools are extremely helpful for gathering detailed data on sewer conditions. While this equipment is popular in the industry, it only represents one kind of inspection method. Non-visual inspection technologies are a category in themselves, and include a range of solutions, including acoustic pipe assessment, electrical leak location and other leak testing, laser profiling, and the use of ground-penetrating radar and geospatial probes.

Acoustic Inspection Methods

Acoustic inspection measures vibrations and/or sound waves to identify pipe irregularities, and it’s often used to identify leaks.

- Acoustic leak detectors listen for the unique sound signature produced by leaks.

- Acoustic blockage detectors measure how sound travels through a pipe. A transmitter at one manhole emits tones and a receiver at the next manhole listens for them. The system then produces a score indicating the level of obstruction in the pipe.

- Acoustic monitoring systems detect the breakage of prestressed wire within a pipe. These systems do not identify individual defects but can be useful in determining when further investigation is required.

- Sonar probes transmit sound waves through water, then measure their reflection to characterize submerged defects and debris.

- Ultrasonic probes transmit high-frequency sound waves through metal pipe walls, then measure their reflection to characterize corrosion/erosion and flaws.

Pipe Leak Location

Electrical leak location detects leaks using an electrically charged probe pulled through a surcharged, nonconductive pipe. Leaks provide a path to ground, which can be measured to determine leak location and

severity.

Smoke, dye and pressure testing can also be used to find leaks, depending on the type of line and where it’s located.

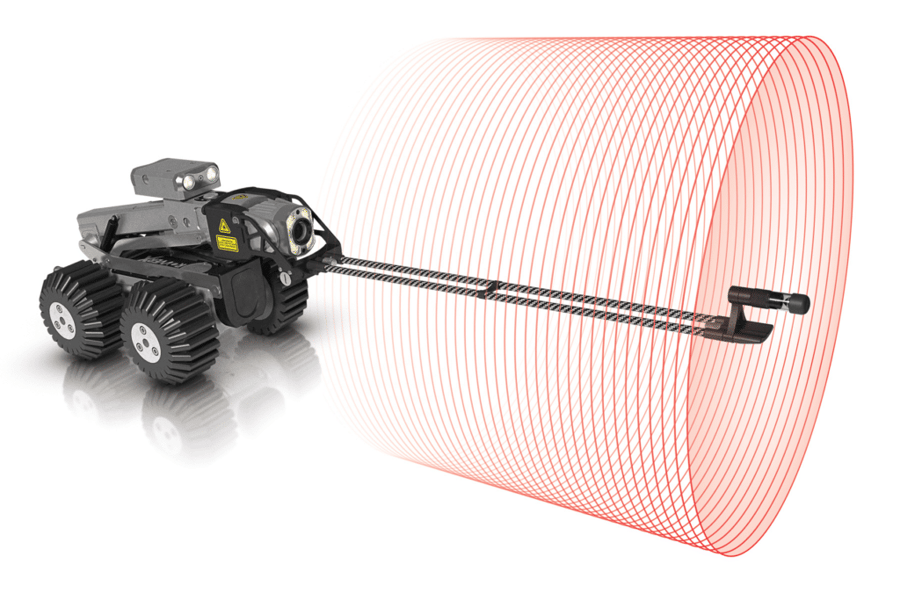

Laser Profiling

Laser Profiling

Laser profiling allows analysis of pipe ovality, alignment, diameter and capacity. To create a profile, a laser probe scans a pipe’s cross section over its entire length. The profile provides detailed geometric information about the pipe, allowing for accurate liner design, quality control on new pipe installations, and measurement of erosion/corrosion rates. Laser profiling can only be used to inspect non-submerged portions of a pipe. It is often used in combination with other inspection methods, like CCTV and/or sonar.

Ground-penetrating Radar

Ground-penetrating radar is used to locate utilities, tunnels and other underground assets. A transmitting antenna emits high-frequency radio waves into the ground. The reflected signal is recorded by a separate receiving antenna and analyzed to determine the position and depth of underground assets. Similar technology can be deployed in-pipe to identify voids in pipe bedding.

Geospatial Probes

Geospatial probes provide real-time, accurate positional data from within a sewer line. They’re ideal for locating and mapping assets. These probes contain accelerometers and other motion-sensing technology to record acceleration, velocity and location. Positional data is recorded as an array of XYZ coordinates, which can be used to create a 3D model of the pipe’s location as the probe moves. This model can be exported to a CAD or GIS platform for further analysis.

Interested in learning more about sewer inspection technologies? Request Envirosight’s free Sewer Maintenance 101 guide, our go-to resource for all things sewer assessment.