The golden age of dam building in the U.S. peaked in the 1960s, with more than 600 dams constructed annually at its height. A vital part of the nation’s infrastructure, dams serve a variety of purposes, from managing flood risk and irrigating arid or semi-arid lands to generating power, providing drinking water for towns or cities, and creating recreational areas.

These dams, and the ones that came before them, played a critical role in the industrialization of the country. As time passes, however, they are facing increasing strain due to heavier precipitation caused by climate change. The structures are aging, and the number of deficient dams, or dams at risk of failing, is climbing. As this happens, dam facility inspection and maintenance to reduce the risk posed by a dam failure to public safety, property, and the environment is increasing in importance.

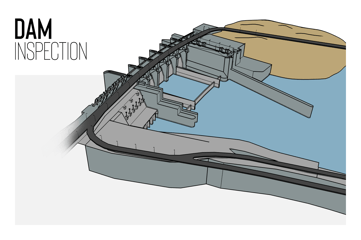

How Dams are Built

There’s no such thing as a typical dam; each varies in how it is constructed due to the unique geology and configuration of the site, the purpose of the dam, and other factors related to site accessibility and materials. Consider, for example, the difference in size, scale and architecture of the massive arch-gravity Hoover Dam—a designated Historic National Landmark that was the tallest dam in the world when it was built in 1935—and that of the flat slab buttress Redridge Steel Dam, which is one of just three steel dams built in the U.S.

Over the last 100 years, dams have largely been constructed using concrete, earthfill, or rockfill. In general, they include a water-containing structure (the dam); a main drain that is used for controlled outflow; toe drains along the dam walls; and pipe conduits, such as spillways and penstocks, that convey discharge. These outlets and pipes are critical to the function of the dam and require regular video inspection and maintenance.

An Ounce of Prevention: Why Inspections Matter

As the adage goes, an ounce of prevention is worth a pound of cure. As manmade structures, dams must be inspected regularly to monitor changes in structural and environmental conditions that could affect the integrity of the dam.

Dam owners and operators conduct a variety of inspections:

- Routine inspection: Also called a patrol, this is a casual assessment in which the dam owner or maintenance or engineering staff periodically walk or drive over dam to see whether anything looks unusual.

- Regular inspection: This assessment is often conducted monthly, in addition to immediately before or after a heavy rainfall, to inspect all of the features of the dam.

- Engineering inspection: Typically performed by someone who specializes in dam engineering, this inspection is often linked to a biannual or annual report required by the state.

The dams’ channels—penstocks, toe drains, sluiceways, outlet/discharge tunnels, and more—require period evaluation as part of the broader dam inspection regimen. With a large dam, the channels are often large enough to inspected visually in person to detect damage or corrosion, and this can require the use of scaffolding or rappelling to give the examiner access to the structure.

Smaller dams, however, require a crawler or other robotic device able to navigate the narrower spaces associated; only conduit pipes with diameters of 36-inches or larger can be inspected by manned entry, assuming that proper OSHA precautions are taken. Crawlers can access tight spaces, such as a 12-by-18 access door, and traverse icy or sharply down-sloping penstocks. They can reliably report on cracks and other pipe defects in addition to leaks and debris. In addition, remote access points are more easily accommodated with a crawler that’s small enough to be portable.

Remote visual inspections also reduce the safety concerns associated with inspections. Dams and spillways are not designed to have people walking across them and can become slippery with accumulated algae and moss. Flows of water through conduits and gates can create hazards or powerful suction. Lastly, the confined spaces themselves present danger to people, who can become wedged in a conduit or find themselves in a zone with low oxygen levels. Unmanned robot or crawler technology can be a better option for these often-hazardous inspections or for conduits that are otherwise inaccessible.

How the ROVVER X is Helping Dam Owners and Operators Ensure Safety

The typical workflow for dam inspection and maintenance includes a precleaning flow test, precleaning video inspection, pipe cleaning, post-cleaning flow test, post-cleaning video inspection, and finally an inclination measurement.

As Breckenridge, Colorado-based Snowbridge has discovered, the ROVVER X provides a versatile option for performing dam inspections that would otherwise be challenging or unsafe. Its portable design reaches remote areas and allows it to travel on ATVs and other small off-road vehicles. Its steerable six-wheel drive makes it uniquely maneuverable when debris is encountered, and smart safety features like clutch/inclinometer interlock prevent the crawler from rolling away on inclines. Fully submersible, its compact crawler profile allows it to inspect lines as small as four to six inches.

“We have the option of going to a remote access point—even if it is on top of a dam,” says Chris Tatro, owner and operator of Snowbridge. “The size and weight of the crawler makes it perfect for our mainline, dam and rehabilitation inspection needs, as well as any other unique projects that come our way.”

Learn more about how the ROVVER X system can help you maintain the integrity of your dam’s outlets and pipes: