Dam Versatile: ROVVER X Performs an Inspection that Scares Away Most Contractors.

Snowbridge, Inc. of Breckenridge, Colorado, is a family-owned wastewater company that has served the commercial, industrial and municipal markets of the Rocky Mountain region for over 35 years. When Chris Tatro, owner and operator of Snowbridge, first set out to find an inspection crawler for his growing business, he knew portability was key—but little did he know that this insight would turn his company into one of the most trusted dam inspection contractors in the region.

Snowbridge started as a rehabilitation company that contracted out all of its inspection work. When Tatro was awarded a large contract to inspect a trailer park, he knew it was finally time to bring inspection capability in-house. He set out looking for a crawler that could handle the unique challenges of the job. “Many of the manholes in this trailer park were 50 feet from street access, so I needed equipment that was robust yet lightweight," Tatro says. "The ROVVER X was everything I had been looking for, and more."

Snowbridge started as a rehabilitation company that contracted out all of its inspection work. When Tatro was awarded a large contract to inspect a trailer park, he knew it was finally time to bring inspection capability in-house. He set out looking for a crawler that could handle the unique challenges of the job. “Many of the manholes in this trailer park were 50 feet from street access, so I needed equipment that was robust yet lightweight," Tatro says. "The ROVVER X was everything I had been looking for, and more."

Not long after purchasing the ROVVER X, Tatro received a call from a dam engineering company asking if Snowbridge could inspect a hydroelectric dam. Always up for a challenge and interested in testing the limits of his new equipment, he said yes.

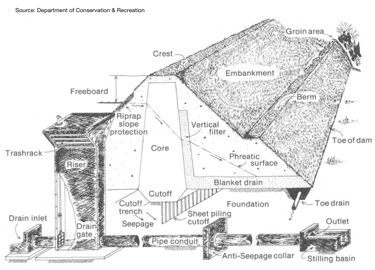

As the demand for water increases, states are focusing on protecting water supplies by investing more in maintaining their dam infrastructure. Dams have a main drain that is used for controlled outflow; toe drains along the dam walls; and pipe conduits that convey discharge. These outlets and pipes are crucial to the function of the dam and require regular video inspection and maintenance. Additionally, engineering companies use inspection reports to make determinations on rehabilitation needs. The typical workflow for dam inspection and maintenance includes a pre-cleaning flow test, pre-cleaning video inspection, pipe cleaning, post-cleaning flow test, post-cleaning video inspection, and finally an inclination measurement.

As the demand for water increases, states are focusing on protecting water supplies by investing more in maintaining their dam infrastructure. Dams have a main drain that is used for controlled outflow; toe drains along the dam walls; and pipe conduits that convey discharge. These outlets and pipes are crucial to the function of the dam and require regular video inspection and maintenance. Additionally, engineering companies use inspection reports to make determinations on rehabilitation needs. The typical workflow for dam inspection and maintenance includes a pre-cleaning flow test, pre-cleaning video inspection, pipe cleaning, post-cleaning flow test, post-cleaning video inspection, and finally an inclination measurement.

When Tatro arrived at his first dam inspection, he learned that many sewer inspection companies decline such jobs. An inspection crawler can get stuck in the dam’s small diameter conduits due to offsets, sharp bends or debris. Dealing with multiple sharp bends requires a crawler compact enough to negotiate turns. Access points are often remote, so having a bulky crawler on a large truck only adds to the difficulty. To top it off, the pipe floor of a dam can be very steep and, depending on the time of year, also icy.

“The ROVVER X was the perfect crawler for the project," Tatro says. "We can carry the three pieces (crawler, cable reel and controls) wherever the inspection requires. We aren’t tied to projects that are street accessible (i.e. mainline sewer projects); we have the option of going to a remote access point—even if it is on top of a dam. The size and weight of the crawler makes it perfect for our mainline, dam and rehabilitation inspection needs, as well as any other unique projects that come our way."

“I didn’t understand just how versatile my system was until that first inspection," says Tatro. "I had a system lightweight enough to carry; compact and maneuverable enough to successfully negotiate turns; and I was able to switch to the grit wheels for the steep icy segments of the inspection. Even the dam engineers were fascinated by the way my equipment worked—ROVVER X made the inspection look effortless."

Last summer alone, Snowbridge successfully inspected over 20 dams.

In many cases, dam engineers don’t have a record of the pipe grade, pitch and depth from when a dam was constructed. ROVVER X’s reporting capabilities help solve this challenge. “We were called out for a project where they were reconstructing the middle of a dam," Tatro says. "The current structure had clay pipes, but the engineers didn’t know much more. They asked us to map the pipes, getting their length, diameter and slope, which we did using the ROVVER X. With the report we provided, the engineers were able to get accurate elevations for the new structure. It was pretty incredible to see how important and useful the information we were able to extract from the inspection was to the engineers.”

“The versatility of ROVVER X is key,” continues Tatro. “We don’t need different systems for different projects—the ROVVER X adapts to any inspection project we come across. Other competitors’ systems require an additional $20k investment in just wheel sets and spacers—with the ROVVER X, a small business like mine can do a lot with just the base system. I have even completed a full video inspection out of my Subaru Impreza. I can say without a doubt, the reason I have been able to work these jobs, and have become a contractor known for specialty work, is solely because of the inspection crawler we have.” Now, 50% of Snowbridge’s video inspection revenue comes from dam inspections.

“The versatility of ROVVER X is key,” continues Tatro. “We don’t need different systems for different projects—the ROVVER X adapts to any inspection project we come across. Other competitors’ systems require an additional $20k investment in just wheel sets and spacers—with the ROVVER X, a small business like mine can do a lot with just the base system. I have even completed a full video inspection out of my Subaru Impreza. I can say without a doubt, the reason I have been able to work these jobs, and have become a contractor known for specialty work, is solely because of the inspection crawler we have.” Now, 50% of Snowbridge’s video inspection revenue comes from dam inspections.

“My advice to anyone looking to enter the pipe inspection market is to make sure you partner with the right sales and service companies—many people don’t realize that you are entering into a long-term partnership with the company you buy your equipment from,” said Tatro when asked for some parting wisdom. “We bought our system from Brian Balchumas of Neverest Equipment. The people at Neverest are great about protecting my investment with preventative maintenance and ensuring that we experience minimal downtime. Consider partners that are invested in the growth and success of your business. I am able to focus on building my business without worrying about my equipment—I know I have experts on-call for that.”

Ready to see the ROVVER X in action? Schedule a demo now: