If at first you don’t succeed, try, try again. Bud Humphries, owner of R.A.H. Solutions, took this message to heart three years ago. The upstate South Carolina-based contractor had historically provided commercial and industrial plumbing service and drain cleaning but knew there was more to explore in the trade.

Topics: Customer Spotlight, Sewer Rehabilitation, Trenchless Rehab, SpeedyLight+ Light Cure for CIPP, CIPP Lining

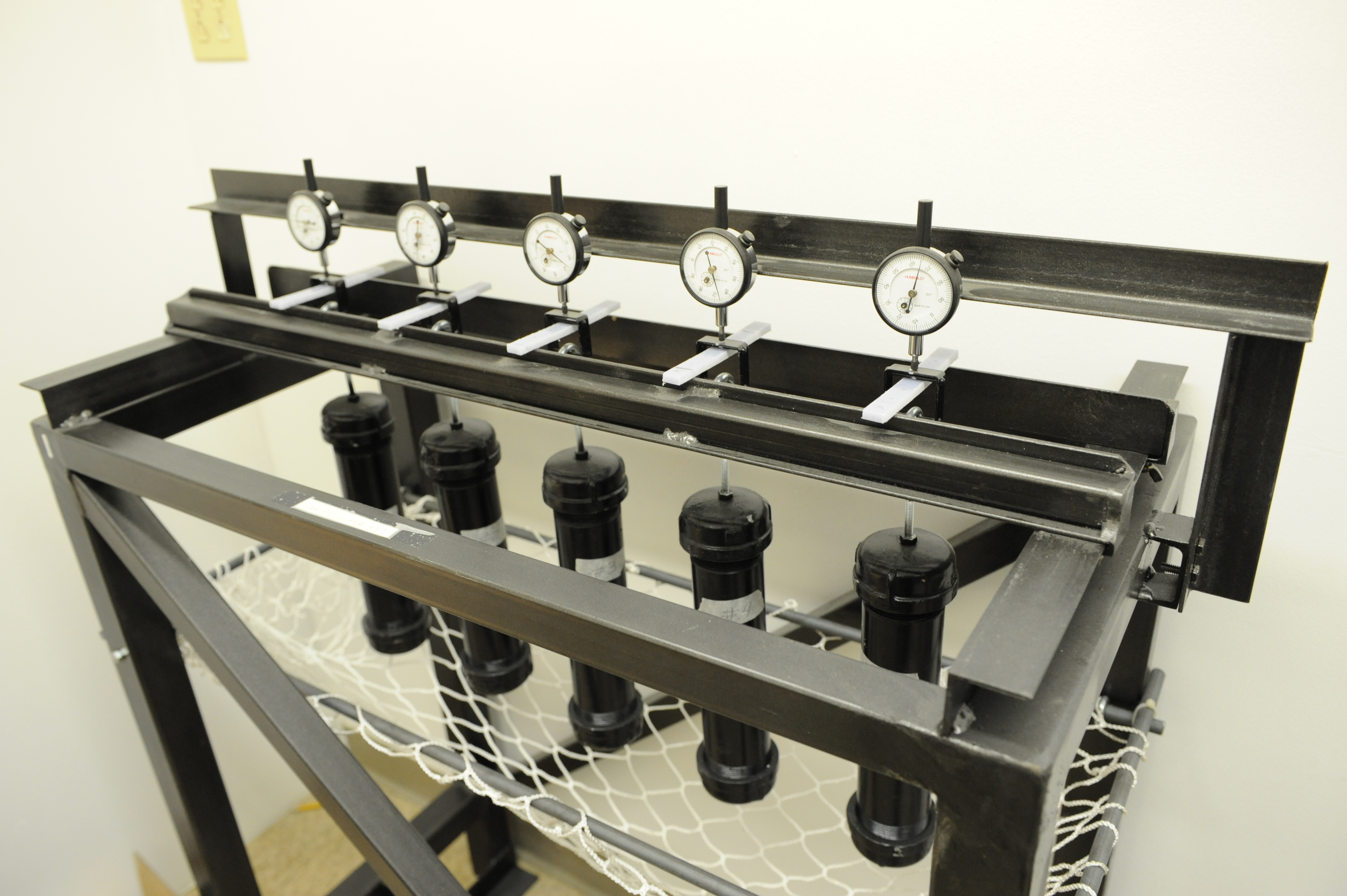

A calibration roller system is used to evenly distribute resin in the liners used in CIPP repairs. It works by feeding the liner onto a roller while the resin simultaneously fills the liner. This process is known as the “wet-out” stage of CIPP rehabilitation. While the new manual and electric rollers from PRT both fulfill this purpose, they operate in slightly different ways.

Topics: Trenchless Rehab, CIPP Lining

Trustworthy Equipment, Trustworthy Support at Savy & Sons

“Game changer.” That’s how Travis Savy, technical director of the pipe lining division at Savy & Sons, describes SpeedyLight+ light curing system for CIPP.

Topics: Customer Spotlight, Sewer Rehabilitation, SpeedyLight+ Light Cure for CIPP

Maintenance Is King: How To Keep Your Pipe Rehab Gear at Peak Performance

The power of routine maintenance cannot be overstated, especially when it comes to sewer rehab and repair equipment. These tools experience serious wear and tear, and sewer lines are often dirty and unpredictable. While this technology is built to withstand rough environments, it isn’t infallible; just a few minutes of cleaning and care per day can help protect your equipment down the road. Looking after your gear helps to extend its service life, avoids downtime from unexpected damage, and can lower overall cost of ownership.

Topics: Sewer Rehabilitation, Trenchless Rehab, Preventative Maintenance

Quick-Lock point repair sleeves are an effective, easy-to-install trenchless pipe repair solution. Nick Sebastian, PRT’s East Coast territory sales manager, gives rehab pros the low-down on Quick-Lock’s features, applications, benefits and more.

Topics: Quick-Lock

Curing During Active Infiltration: Which Cure Works Best?

Cured-in-place pipe (CIPP) installation is made more difficult by active infiltration, which occurs when groundwater seeps through cracks, joints or manholes into sewer pipes. New CIPPs should be tight-fitting and jointless to seal off any possible points of entry for infiltration. Unfortunately, CIPP does not eliminate infiltration from entering the existing host pipe. Infiltration is dangerous to the installation process because too much flow can wash the resin off of the new liner and/or prevent the liner from installing correctly. However, the type of cure used for installation can make a difference in the effects of infiltration.

Topics: Sewer Rehabilitation, Trenchless Rehab, SpeedyLight+ Light Cure for CIPP

Plumber magazine recently featured the Micro S Light+ in a story following Norman Hostetler, a trenchless specialist at TCI Plumbing in Goodfield, Illinois. Hostetler explains how the Micro S Light+ has vastly improved his process for opening up branch lines after lateral relining. He notes that the system lets him cut reinstatement time in half.

Topics: Sewer Cutters

How the Micro S Light Cutter Can Help Your Team Do More, at Lower Cost

PRT’s Micro S Light+ is a small-diameter cutter suited for prep and reinstatement work in drains and laterals alike. The system is designed for 3-9” pipe rehab, but don’t let its smaller circumference fool you—the cutter has an air-powered motor delivering maximum torque.

Topics: Sewer Rehabilitation, Sewer Cutters

When a pipe rehab crew installs a CIPP liner, they typically do the job in just a few hours, and then move on to the next project. But that’s not the end of the story. CIPP is designed to last for decades, and the wastewater systems that use it need to be confident in its efficacy. In most cases, installers are required to submit a sample of every liner installed for third-party testing. Only once testing is complete and the results are approved and reported is the job really “done.”

Topics: CIPP Lining

It’s easy to get complacent in a job. When you do the same tasks day after day—same crew, same truck, same equipment—it’s common to “check out” mentally from time to time.

Don’t check out of trenching safety.

About PRT

Pipeline Renewal Technologies delivers innovation to processes ranging from pipe point repair to relining and lateral reinstatement. Cutting edge technology, combined with dependability and support, have made us the industry's partner of choice.

Subscribe to Email Updates

Recent Posts

Posts by Topic

- Trenchless Rehab (21)

- Sewer Rehabilitation (17)

- Quick-Lock (16)

- Sewer Cutters (11)

- SpeedyLight+ Light Cure for CIPP (11)

- Point Repair (8)

- Resources (8)

- CIPP Lining (7)

- Customer Spotlight (5)

- Business Resources (4)

- Sewer IQ Quiz (4)

- Training (3)

- WWETT (3)

- Inflow and Infiltration (2)

- Preventative Maintenance (2)

- Product Features (2)

- ROVVER X (2)

- Resource Allocations (2)

- Sewer Infrastructure (2)

- LEDRig (1)

- PACP (1)

- Press Release (1)

- SewerTronics (1)

- Standards and Compliance (1)

- Verisight Pro (1)

- Video (1)

- Workflow (1)