What's your Light-based Curing Sewer IQ? Take Our Quiz to Find Out

Topics: Sewer IQ Quiz

Cured-in-place pipe for trenchless rehabilitation has made major strides since its inception 50 years ago. New advancements in technology have helped the installation process become safer and more efficient, and made CIPP a stronger, more durable solution for repairing failing pipes.

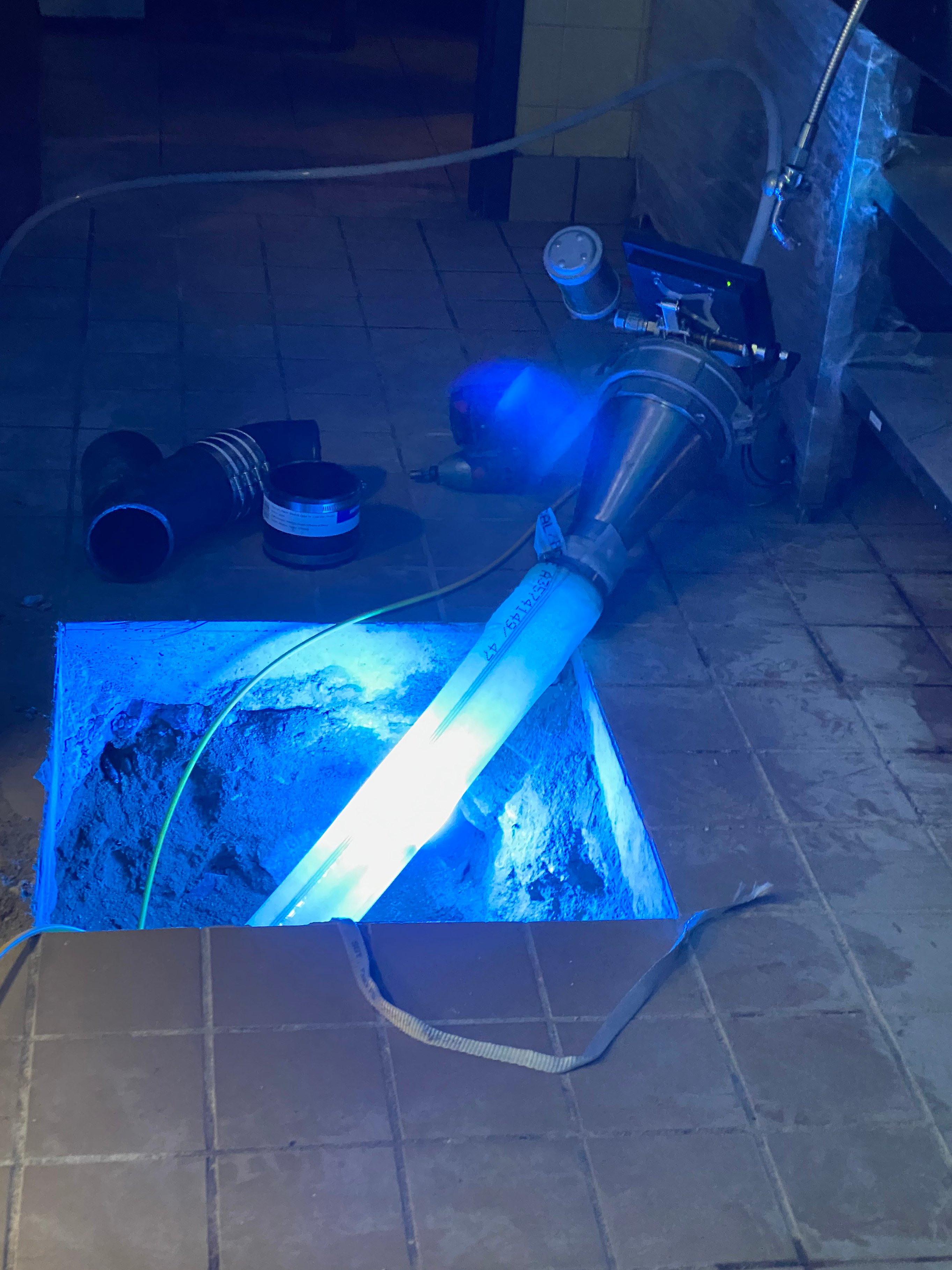

Topics: SpeedyLight+ Light Cure for CIPP

East Coast Contractor Cures With Confidence Using SpeedyLight+

Family-owned and -operated wastewater contractor, Royal Flush, blends both traditional and modern practices into its business. While the company embraces a rich history in the industry and a close-knit team, it’s also quick to invest in new technology that will help it stay ahead of the competition.

Sewer School: What is Light-based Curing for CIPP?

In the world of trenchless pipe repair, light-based curing is a more recent advancement for installing cured-in-place pipe (CIPP). It’s also become a favored one for a handful of reasons.

Tips for Growing Your Contracting Business in 2021

After a year of uncertainty for many industries, it’s important to be prepared for 2021. If you’re strategizing ways for your wastewater contracting business to continue to grow and succeed in the new year, here are some tips for your company.

Trenching and excavation come with inherent dangers. While regulators and industry organizations have worked hard in recent years to reduce associated risks and damages, the results have been varied.

What to Know Before Renting Sewer Rehab Equipment

Renting sewer rehabilitation equipment gives municipalities and contractors extra flexibility. The more equipment at a crew's disposal, and the wider the variety, the more jobs they can perform and bid on. However, purchasing isn’t always an immediate option.

Topics: Quick-Lock, Sewer Rehabilitation, Sewer Cutters, Trenchless Rehab, SpeedyLight+ Light Cure for CIPP

A crucial step in setting any sewer inspection or rehab team up for success is building a culture of safety. Regardless of the industry, developing and promoting safe practices in the workplace should be on every leadership member’s agenda. When implementing or building out safety culture, it’s important to take a methodical approach.

Choosing the Right Trenchless Sewer Rehab Method

Trenchless sewer rehabilitation offers wastewater professionals a less invasive method for repairing damaged or deteriorating parts of our underground infrastructure. Before trenchless rehab methods were introduced, wastewater professionals relied on dig-and-replace, which required excavation along the full length of the defective pipe to remove and replace it completely. This was not only disruptive, but also costly and precarious work.

Instead, trenchless technologies offer a way to restore the existing pipe’s structural integrity without ever taking it out of the ground.

Topics: Trenchless Rehab

How to Find Government Wastewater Contract Opportunities

Wastewater operators turn to contractors for a variety of reasons—they may need limited or specialized services, lack the staff, resources or equipment for a project, or have unique budget restrictions. The result is that contractors are an essential part of ensuring that Americans have safe, efficient and affordable utilities in their communities. And with budgets in flux and America’s infrastructure in decay, there’s no end to the opportunities available for wastewater rehab, inspection and maintenance businesses. Small contractors hoping to get into the game just need to know where to look.

Topics: Resources

About PRT

Pipeline Renewal Technologies delivers innovation to processes ranging from pipe point repair to relining and lateral reinstatement. Cutting edge technology, combined with dependability and support, have made us the industry's partner of choice.

Subscribe to Email Updates

Recent Posts

Posts by Topic

- Trenchless Rehab (21)

- Sewer Rehabilitation (17)

- Quick-Lock (16)

- Sewer Cutters (11)

- SpeedyLight+ Light Cure for CIPP (11)

- Point Repair (8)

- Resources (8)

- CIPP Lining (7)

- Customer Spotlight (5)

- Business Resources (4)

- Sewer IQ Quiz (4)

- Training (3)

- WWETT (3)

- Inflow and Infiltration (2)

- Preventative Maintenance (2)

- Product Features (2)

- ROVVER X (2)

- Resource Allocations (2)

- Sewer Infrastructure (2)

- LEDRig (1)

- PACP (1)

- Press Release (1)

- SewerTronics (1)

- Standards and Compliance (1)

- Verisight Pro (1)

- Video (1)

- Workflow (1)